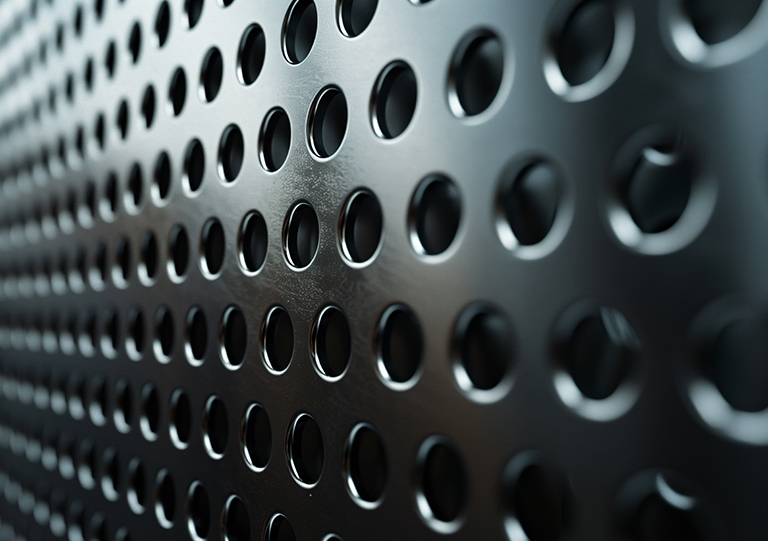

5 Axis Laser Cutting & Welding

Sirius Aerospace's 5-Axis Laser Cutting facility offers an economical solution for profiling holes and trimming pressed and drawn components without the need for expensive hard tooling.

- Ideal for prototyping and small to medium batch production where piercing and crop tooling is not cost-effective or long lead times for hard tooling are unacceptable.

- State-of-the-art equipment and advanced off-line 3D programming software allow file imports and application of precise cutting paths.

- Capable of processing complex pressings, formed parts, and spinnings in mild steel, aluminium, and stainless steel on the 5-Axis machine.

- Can handle parts up to 5m x 1.5m in size.

- Smaller components up to 1.5m x 1.2m can be processed more efficiently using the twin CAB facility.

- 5-Axis laser cutting provides design flexibility, enabling the processing of virtually any shaped object made from sheet metal.